541-942-5920

Click Image for full size

| Daytona CD1 | Crane HI-6 | MSD 6 and............................ MSD Digital6 |

|

Feature |

Daytona Sensors CD-1 P/N 102003 |

Crane HI-6DSR P/N 6000-6424 |

MSD Digital 6 P/N 6520 |

|

RPM Limiting Stages |

Three. Third (launch) stage set via PC Link CDPro- 2 Limiters-NHRA Pro Bracket Legal |

Two |

Two |

|

Retard Capability |

Driver adjustable retard, boost retard, and 0-10º high gear retard capability |

Driver adjustable retard and boost retard capability |

0-10º high gear retard capability only |

|

Start Retard |

Yes - Mapped in |

No |

Yes |

|

Timing Advance Capability |

Yes. RPM based advance curve or 3D timing map based on RPM and manifold pressure. NOS or Blower/turbo applications |

No |

No |

|

Data Logging |

Yes. Internal 16 Mbit DataFLASH memory CD-Pro has no Data Logging by NHRA Rules |

No |

No |

|

General Purpose Input/Output Terminals |

Three |

None |

None |

|

Optional PC Link |

Yes. Can upload custom advance curves and download logged data |

No |

No |

| Electronic | Surface mount technology | Surface mount technology | Rocket Radio wire and silicone electronics mounting |

All three units utilize an extruded aluminum housing with stamped aluminum end plates that holds a single printed circuit board (PCB) assembly. Power devices are held against the lower left side of the housing by a heat sink bar. The CD-1 uses a wire harness for battery power, ground, and coil connections and a 12 terminal Deutsch connector for signal connections. The Crane HI-6DSR uses a wire harness for all connections. The MSD Digital 6 uses a wire harness for all connections except the tach signal that is brought out on a non-locking tab connector. All CD-1 and Crane HI-6DSR units are fully encapsulated with soft urethane material. MSD units are inconsistent. Some production units are fully encapsulated. The sample we obtained was only conformal coated and used hot melt adhesive to secure larger components that could vibrate loose. In general, any automotive electronics mounted under hood should be fully encapsulated to avoid failures due to moisture intrusion.

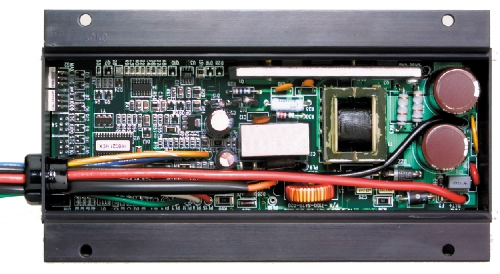

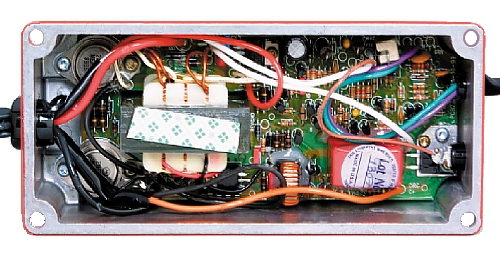

Comparative internal views of the three units are shown below.

The pictures are scaled to the same relative dimensions and speak for themselves. The CD-1 has a neat, organized layout with high power devices spaced wide apart for improved heat dissipation. The wire harness connections are routed far away from sensitive digital circuitry. With the exception of high power devices, switches, and connectors, all other components are surface mount. The Crane HI-6 shown (the HI-6DSR is identical with the exception of two additional switches) has older technology with fewer and larger surface mount components. The MSD Digital 6 relies entirely on obsolete technology through-hole type components. Both the Crane and MSD units have jumbled wire harness connections that are routed directly over sensitive digital components.

Internal View of Daytona Sensors CD-1 with Level 5 Surface Mount Technology Electronics

Internal View of Crane HI-6

Internal View of MSD 6

Internal View of MSD Digital 6

TECHNOLOGY

All three units are capacitive discharge (CD) type ignitions with similar output characteristics and are suitable for racing use on high performance V8 engines running up to 10,000 RPM. All three units have a flyback type switching power supply in the DC/DC converter stage that charges up the energy storage capacitor. And all three units are based on modern IGBT (insulated gate bipolar transistor) technology in the coil driver output stage.

The CD-1 utilizes an Atmel ATmega64 FLASH based processor versus the Microchip PIC16C series one-time-programmable processors found in the Crane and MSD units. Both Atmel and Microchip processors use fast RISC technology, but the newer Atmel processor executes instructions four times faster. The Atmel processor stores the program in FLASH memory that can be reprogrammed using the PC link, even after final assembly. This feature makes it possible for us to offer custom versions of the CD-1 without minimum production runs. The Atmel processor also has EEPROM (electrically erasable programmable read-only memory) for storage of custom advance curves and other user programmable parameters. None of these capabilities are possible with the Microchip processors used in the Crane and MSD units.

As mentioned above all three units have a flyback type switching power supply in the DC/DC converter stage. The DC/DC converter is a critical part of any CD ignition system. Efficiency is the most important criteria for the DC/DC converter. Lower efficiency means greater heat dissipation, higher operating temperatures, and reduced long term reliability. The Crane HI-6 DC/DC converter has a small E-core type transformer and older MOSFET (metal-oxide-semiconductor field-effect transistor) switching device that limits the efficiency to about 70%. That means that 30% of the energy supplied by the battery to charge the capacitor is lost as heat. The MSD DC/DC converter utilizes similar MOSFET technology but has an improved toroidal transformer that boosts efficiency to about 80%. The CD-1 utilizes the latest MOSFET technology, a new patented power supply topology known as boundary-mode control, and a novel regenerative snubber network that recovers energy otherwise lost during power device switching. The net result is over 90% efficiency and the ability to maintain full output even if the battery voltage drops well below 10 volts.

The Crane and MSD units lack internal data logging. The CD-1 has an Atmel AT45DB161D 16 Mbit Data FLASH memory that allows data logging at rates ranging from 2 samples/second for 5 hours to 100 samples/second for 6 minutes. When equipped with an optional manifold absolute pressure (MAP) sensor and vehicle speed sensor, the CD-1 system will log data including RPM, vehicle speed, manifold pressure, ignition timing, battery voltage, and status of the various inputs and outputs.

The Crane and MSD units lack programmable general purpose input/output terminals. The CD-1 has three such terminals that can be programmed for a variety of functions including data logging vehicle speed or analog 0-5 volt signals such as throttle position, and/or controlling devices such as a shift light or nitrous system. For complete details, refer to the CD-1 instructions.

If the Crane and Daytona units seem similar, they are and were both designed by the same Electronics Engineer, the Carne unit was his earlier work.

R.I.P. Chris, your Genius lives on.

|

|

Daytona CD-1 MSRP $585.00 On Sale Now call for pricing |

MSD 7-2 $539.00 |

|

Coil Output |

40,000V |

40,000V |

|

Multi Spark |

To 3,300 RPM |

To 3,300 RPM |

|

Burn Degrees |

20 |

20 |

|

Processor |

16 MIPS micro-controller |

4 MIPS micro-controller |

|

Rev Limiters |

3 total (2 set on rotary switches) |

3 |

|

Spark Output |

135 mJ |

190 mJ |

|

Coil |

Included |

HVC-2 $180.00 |

|

Data Acquisition Inputs |

5 inputs |

None |

|

Data Acquisition Memory |

16 MBit Data FLASH |

None |

|

Current Draw |

5 Amp at 8,000 RPM |

8.8 Amp at 8,000 RPM |

|

Min Operating Voltage |

6V |

12V |

|

Max Operating Voltage |

20V |

18V |

|

Size |

7.0” x 5.25” x 1.9” 70 CI |

8.5” x 4.5” x 2.25” 86CI |

|

Programmable Timing Curve |

Standard |

MSD 8975-$242.00 |

|

CD Voltage Output to Coil |

535V |

535V |

|

3D Timing Map |

Standard |

No |

|

2D Timing Map |

Standard |

No |

|

Boost Proportional Retard |

Yes |

No |

|

Input Terminals |

1 General purpose |

0 |

|

Input/Output Terminals |

2 General purpose |

0 |

|

USB Interface |

Laptop Upload Cable connection |

No capabilities |

|

Total cost |

With Coil and Up Link Cable MSRP $595.00 Call for Sale Price You won't believe the actual Price from FBO! |

Add this all up to match the CD-1 $961.00 You still won't be able to match the all the features of the CD-1 |

Q. So my MSD box is full of glue?

Steve, Co.

A. It appears so ...poor horses

Q. I have a MSD 6AL, 8737, 8671, 8673, 8670, coil and Pro Billet distributor. I have a miss at 6200 to 6700 and then it quits can you tell me what's wrong?

A. Maybe "MSD 6AL, 8737, 8671, 8673, 8670" ... all in one unit with the CD1 and CD-Pro. We can test them all for $100.00, replacements are $200? EBay and buy a CD1, makes more sense to me.

Q. Wow big difference in the wiring quality.

A. I would agree, the CD1 is all level 5 electronics from this century

Q. I'm waiting for MSD to publish these pictures

A. Me Too, but I'm not holding my breath.

Q. Are these 100% Made in USA?

A. As with most multi component products we can't get away from importing some electronic components to build them, many items are no longer made in the USA especially in electronics. (ask one of your 9.1%, closer to 20% unemployed neighbors) Daytona always strives to find USA manufacturers that can make as many of the components as possible. All the extrusions and assembly is done in Florida.

They employ many hard working skilled Americans, all good jobs with benefits and a good living wage.

The recent CoO Laws (Country of Origin) mandate that any product with less than 50% Value in American made parts and labor can not be labeled "Made in America". Haven't looked at the recent MSD Packaging. Call them?

Q. Lots of mumbo jumbo electronics gibbley garb, do they work!

A. I run it and it's always flawless ....2006 Pro Champion, 2006 Mopars at the Strip Pro Champion, 2010 Pro-Bracket Track Champion, 2011 Oregon State Champion, 2016 Pro Champion, 2017 runner up, 5 Walleys on the shelf. Ignition was always flawless... 13 years never a hick-up, driver not so perfect. Over 10,000 units in service worldwide and all flawless.

Do a simple Google search "MSD Failures" and then "Daytona CD1 Failures"

541-942-5920